Robotic palletizing and depalletizing technology represents a cornerstone of modern industrial automation, revolutionizing how goods are handled in warehouses and factories worldwide. At its core, this technology leverages advanced robotic systems to stack and unstack items onto pallets efficiently, reducing human labor and enhancing operational precision. The principles driving this innovation stem from a synergy of mechanical engineering, sensor integration, and intelligent programming, enabling seamless adaptation to diverse logistical challenges.

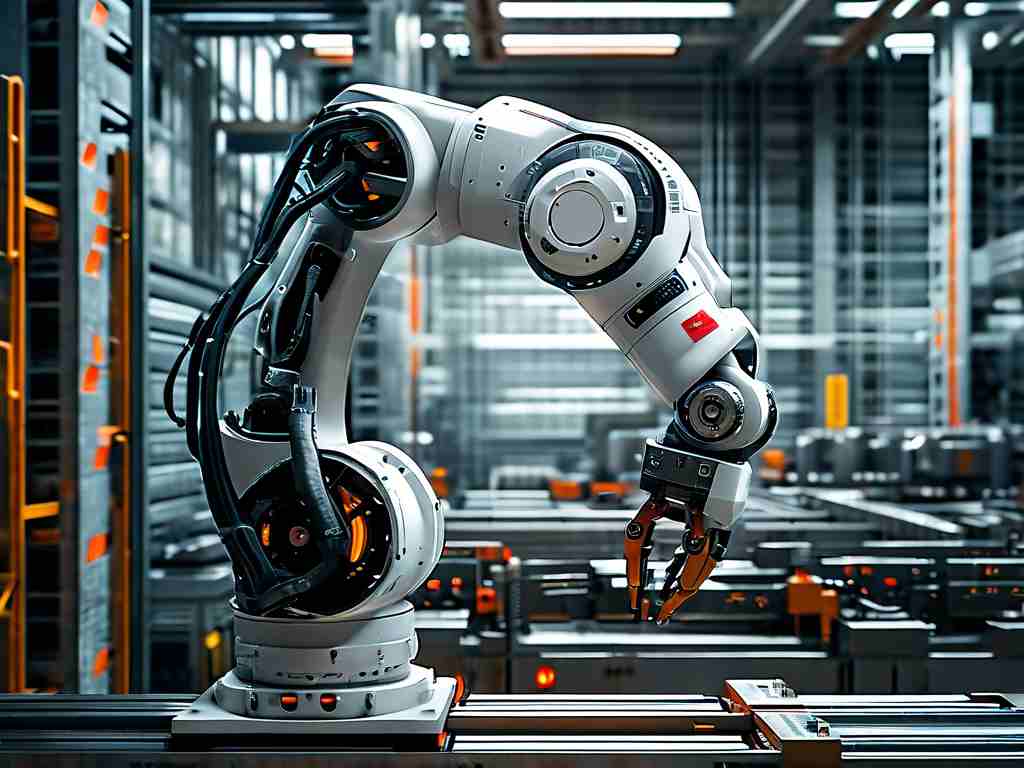

Fundamentally, the technology relies on industrial robotic arms equipped with specialized end effectors such as vacuum grippers or mechanical clamps. These arms execute precise movements guided by servo motors and controllers, ensuring accurate positioning of goods during stacking or destacking processes. For instance, in a typical depalletizing operation, the robot uses sensors to detect the location and orientation of items on a pallet before gently lifting and transferring them to conveyor belts or other stations. This motion control is underpinned by kinematics algorithms that calculate optimal paths, minimizing collisions and maximizing throughput in high-volume environments. Such principles ensure that robots can handle varying load sizes and weights without compromising speed or safety, a critical advantage in today's fast-paced supply chains.

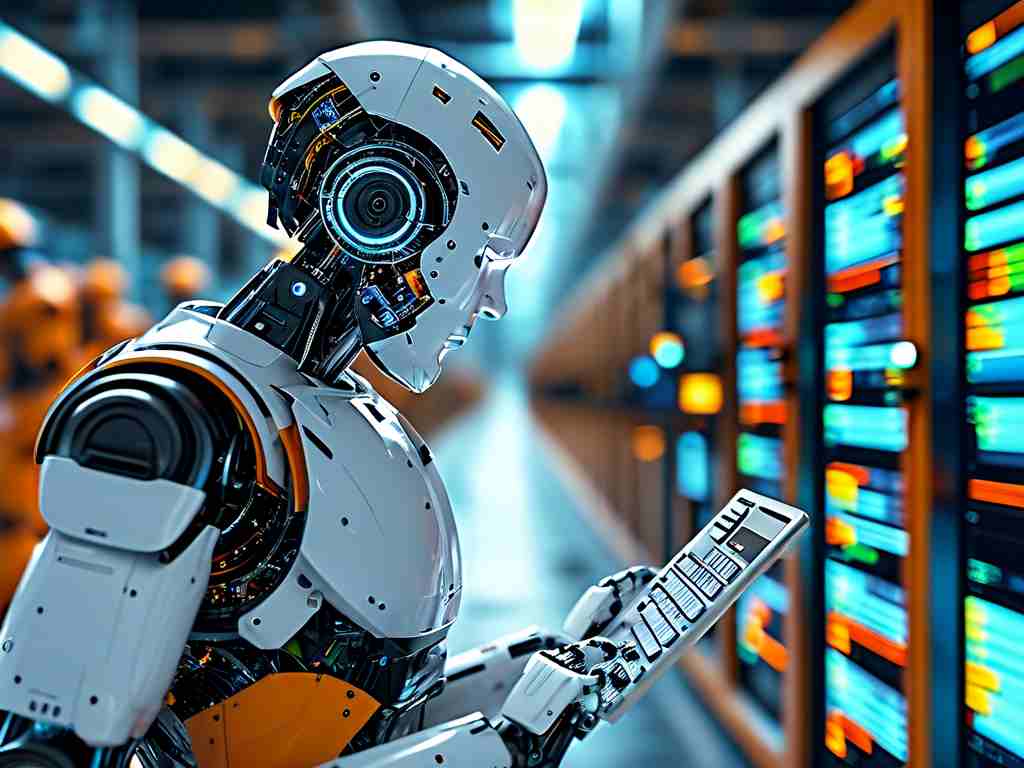

Sensor technology plays a pivotal role in the underlying principles of robotic palletizing and depalletizing. Vision systems, including cameras and 3D scanners, provide real-time feedback on object dimensions, shapes, and positions. This allows the robot to adjust its grip and trajectory dynamically, compensating for inconsistencies in pallet loads or environmental factors like lighting changes. In some setups, force-torque sensors detect resistance during handling, enabling gentle manipulation of fragile items to prevent damage. These sensory inputs feed into the control unit, which processes data using machine learning algorithms to improve decision-making over time. As a result, the system becomes more adaptive and reliable, learning from past operations to optimize future tasks without constant reprogramming.

Programming and software integration form another essential layer of the technology's principles. Engineers use platforms like ROS (Robot Operating System) or proprietary interfaces to code sequences that define how robots interact with pallets. For example, a simple code snippet might instruct the arm to move to a specific coordinate, activate the gripper, and lift an item:

move_to_position(x, y, z);

activate_gripper();

lift_item(speed=medium);This code-based approach allows customization for different product types, pallet configurations, and workflow requirements. Moreover, integration with broader systems such as PLCs (Programmable Logic Controllers) or WMS (Warehouse Management Systems) ensures seamless coordination across the facility. Data from these integrations enables predictive maintenance, where algorithms monitor wear on components and schedule repairs proactively, reducing downtime and extending equipment lifespan. This holistic software framework transforms raw mechanical actions into intelligent, autonomous operations that align with lean manufacturing goals.

The applications of robotic palletizing and depalletizing principles span numerous industries, driving efficiency gains in sectors like food and beverage, pharmaceuticals, and e-commerce. In beverage plants, robots stack crates onto pallets at high speeds, maintaining hygiene standards by minimizing human contact. Similarly, in logistics hubs, depalletizing robots unload incoming shipments swiftly, accelerating order fulfillment while reducing ergonomic risks for workers. These real-world implementations highlight the technology's versatility, as it adapts to environments ranging from controlled clean rooms to rugged warehouses. By automating repetitive tasks, businesses achieve significant cost savings—studies show reductions in labor expenses by up to 50%—while boosting throughput and error reduction rates.

Despite its benefits, the technology faces challenges that influence its adoption and evolution. High initial investment costs for robotic systems can be a barrier for smaller enterprises, though falling prices and modular designs are making it more accessible. Maintenance demands also arise, as wear on mechanical parts or sensor calibration issues may require skilled technicians. However, ongoing advancements in AI and IoT are addressing these hurdles, with trends pointing toward collaborative robots that work alongside humans safely and cloud-based analytics for remote monitoring. Looking ahead, the fusion of 5G connectivity and edge computing promises even smarter, faster systems capable of real-time optimization in complex supply chains.

In , the principles of robotic palletizing and depalletizing technology underscore a transformative shift toward smarter, more resilient industrial operations. By harnessing robotics, sensors, and advanced programming, this innovation not only enhances productivity but also fosters safer workplaces and sustainable practices. As industries continue to embrace automation, these core principles will drive further refinements, ensuring that the future of material handling remains efficient, adaptable, and human-centric. Ultimately, this technology exemplifies how engineering ingenuity can solve real-world problems, paving the way for a new era of logistical excellence.