In the rapidly evolving landscape of artificial intelligence and automation, Dalian Maple Leaf Intelligent Robotics Technology (DMLIRT) has emerged as a trailblazer in China's robotics industry. Headquartered in Dalian – a coastal city renowned for its technological innovation – the company combines cutting-edge AI algorithms, advanced manufacturing capabilities, and sustainable development principles to redefine industrial and service robotics.

Technological Innovations

At the core of DMLIRT's success lies its proprietary neural network architecture, MapleCore™, which enables robots to process environmental data 40% faster than conventional systems. This breakthrough has been particularly transformative in manufacturing, where their flagship product, the ML-3000 industrial arm, achieves micron-level precision while reducing energy consumption by 22%. The company's recent integration of quantum computing-inspired algorithms allows predictive maintenance capabilities, slashing equipment downtime by up to 35% across automotive production lines.

Applications Across Industries

-

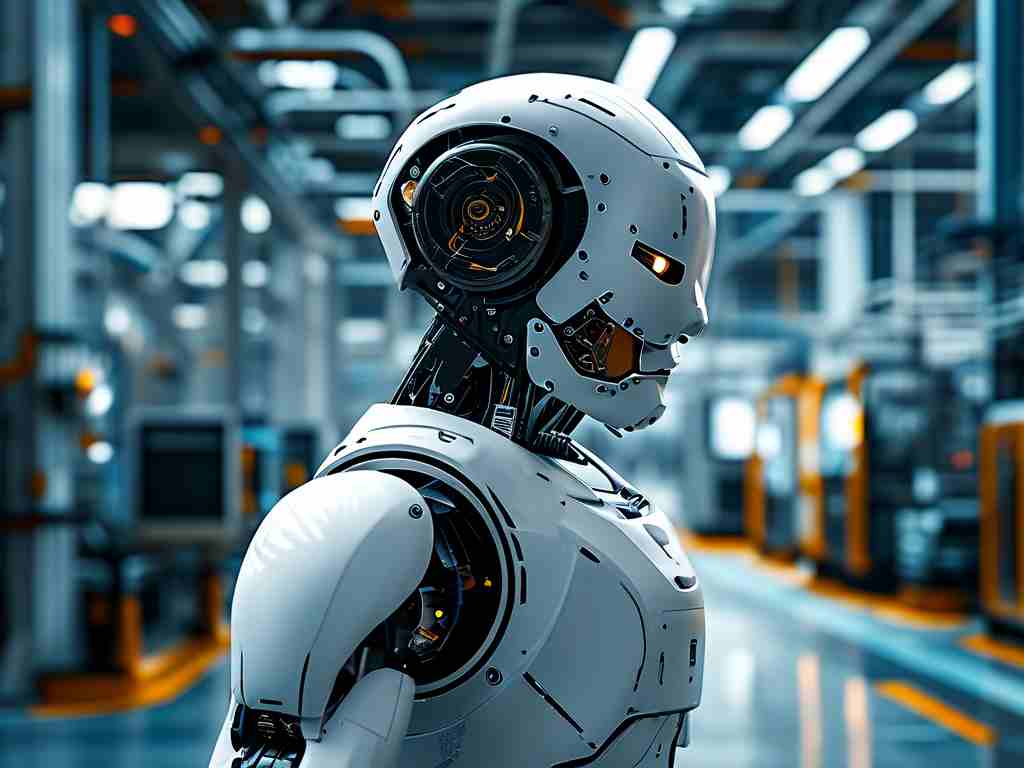

Smart Manufacturing

DMLIRT's collaborative robots (cobots) now operate in over 200 factories worldwide, working alongside human technicians. Their patented force-feedback technology ensures safe interaction, while machine vision systems can identify defects invisible to the human eye. A notable implementation at a major electronics manufacturer reduced product rejection rates from 1.2% to 0.15% within six months.

-

Healthcare Revolution

The company's medical division developed the "Surgeon's Third Hand" robotic assistant, which has completed 8,000+ minimally invasive surgeries with 99.98% operational accuracy. This system combines real-time haptic feedback with AI-powered tremor filtration, enabling procedures previously deemed too delicate for robotic intervention. -

Agricultural Automation

Addressing China's rural labor shortage, DMLIRT's AgriBot series utilizes multispectral imaging and soil analysis modules to optimize crop yields. Trials in Liaoning Province demonstrated a 17% increase in rice production while reducing pesticide usage by 30%.

Sustainable Development Focus

DMLIRT leads in eco-conscious robotics design. Their energy recovery systems capture kinetic energy from robotic movements, powering up to 15% of a factory's lighting needs. The company's "Green Manufacturing Index" – now adopted as an industry standard – evaluates robotics systems based on lifecycle carbon footprint and recyclability.

Global Competitiveness

Despite fierce international competition, DMLIRT holds 214 patents across 15 countries. Strategic partnerships with German engineering firms and Singaporean AI labs have accelerated cross-border technology transfer. The company's R&D expenditure reached 18.7% of total revenue in 2023, focusing on swarm robotics and self-learning systems.

Ethical AI Framework

Pioneering responsible innovation, DMLIRT established China's first Ethics Review Board for Robotics. Their "Three Laws+" protocol expands on Asimov's principles, requiring robots to:

- Prioritize environmental protection in decision-making

- Maintain transparent data provenance

- Preserve human cultural heritage in automated processes

Workforce Transformation

Contrary to job displacement fears, DMLIRT's implementation model creates new roles. At the Dalian Smart Port – Asia's first fully automated harbor – robot technicians and AI trainers now constitute 60% of the workforce. The company's vocational training programs have upskilled 12,000 workers in robotics maintenance and programming since 2020.

Future Roadmap

Looking ahead, DMLIRT aims to launch the world's first self-evolving robotics platform by 2026. This system will combine neuromorphic computing with generative AI, enabling robots to redesign their own components for optimized performance. Concurrently, their lunar robotics division is developing autonomous systems for China's upcoming moon base projects.

Challenges and Opportunities

While facing semiconductor supply chain constraints and global trade uncertainties, DMLIRT's adaptive manufacturing strategy – utilizing 3D-printed microfactories – ensures resilience. The company's vision extends beyond commercial success; it seeks to establish Dalian as a global robotics innovation hub, bridging technological advancement with human-centric design.

In , Dalian Maple Leaf Intelligent Robotics Technology exemplifies China's strategic shift towards high-value manufacturing and AI leadership. By balancing innovation velocity with ethical considerations, the company not only advances robotic capabilities but also charts a sustainable path for human-machine coexistence in the 21st century.