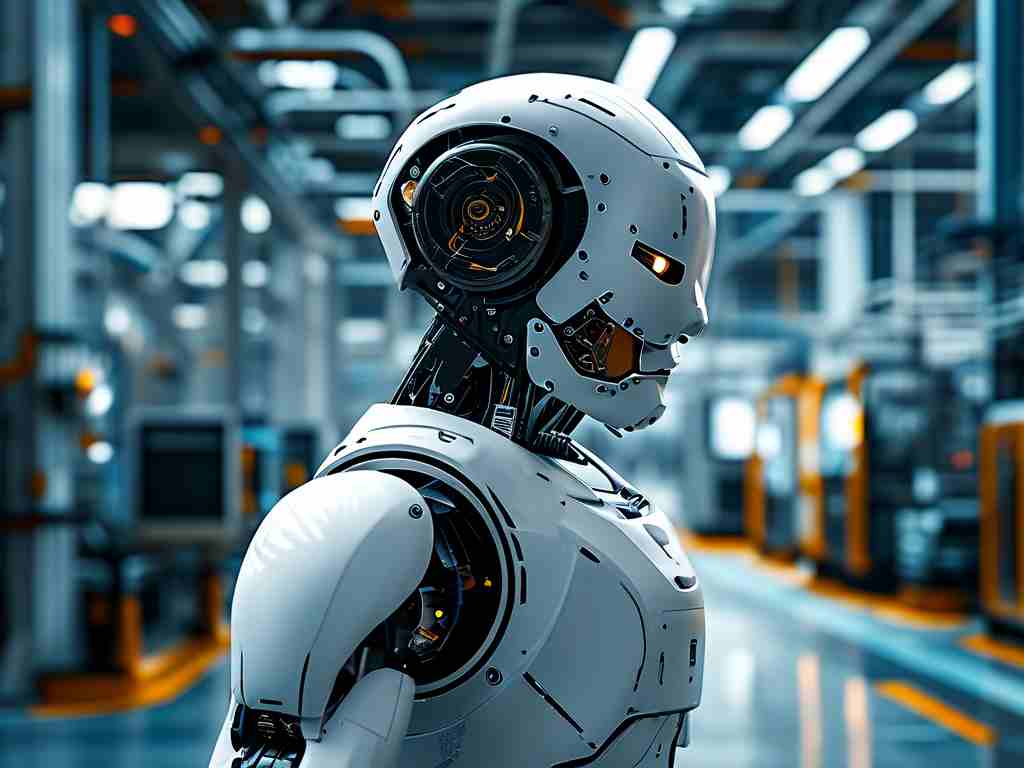

The rapid evolution of industrial automation has positioned robotics as a cornerstone of modern manufacturing. Among global leaders in this field, ABB Robotics stands out for its cutting-edge solutions, and its presence in Xuzhou, China, exemplifies how regional hubs are driving technological progress. This article explores the advancements in Xuzhou ABB industrial robotics, their applications, and their transformative impact on industries worldwide.

Xuzhou: A Hub for Industrial Innovation

Xuzhou, a historically significant city in Jiangsu Province, has emerged as a strategic base for advanced manufacturing. Its robust infrastructure, skilled workforce, and government support for technology adoption make it an ideal location for ABB’s operations. ABB’s Xuzhou facility focuses on developing industrial robots tailored to sectors like automotive, electronics, and logistics. By integrating artificial intelligence (AI), machine learning, and IoT connectivity, these robots are redefining efficiency, precision, and scalability in production lines.

Key Technologies in Xuzhou ABB Robotics

-

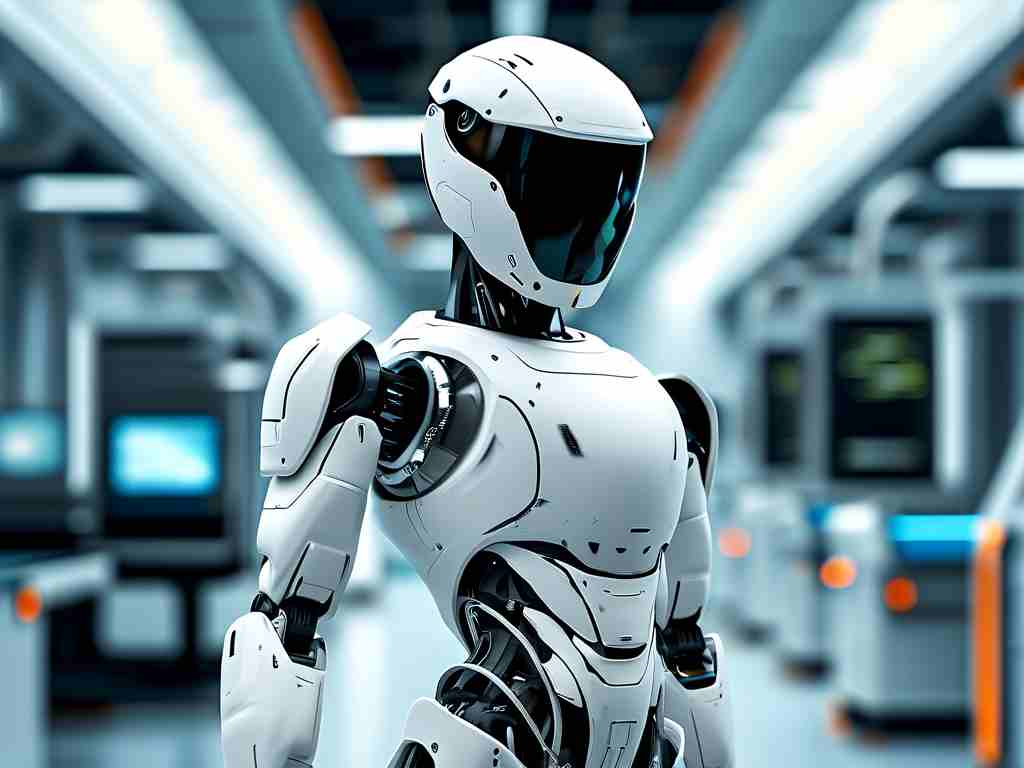

Collaborative Robots (Cobots):

ABB’s YuMi® series, produced in Xuzhou, exemplifies the shift toward human-robot collaboration. These cobots are designed to work safely alongside humans, handling delicate tasks such as assembly and quality inspection. Their flexibility allows manufacturers to adapt quickly to changing demands, reducing downtime and operational costs. -

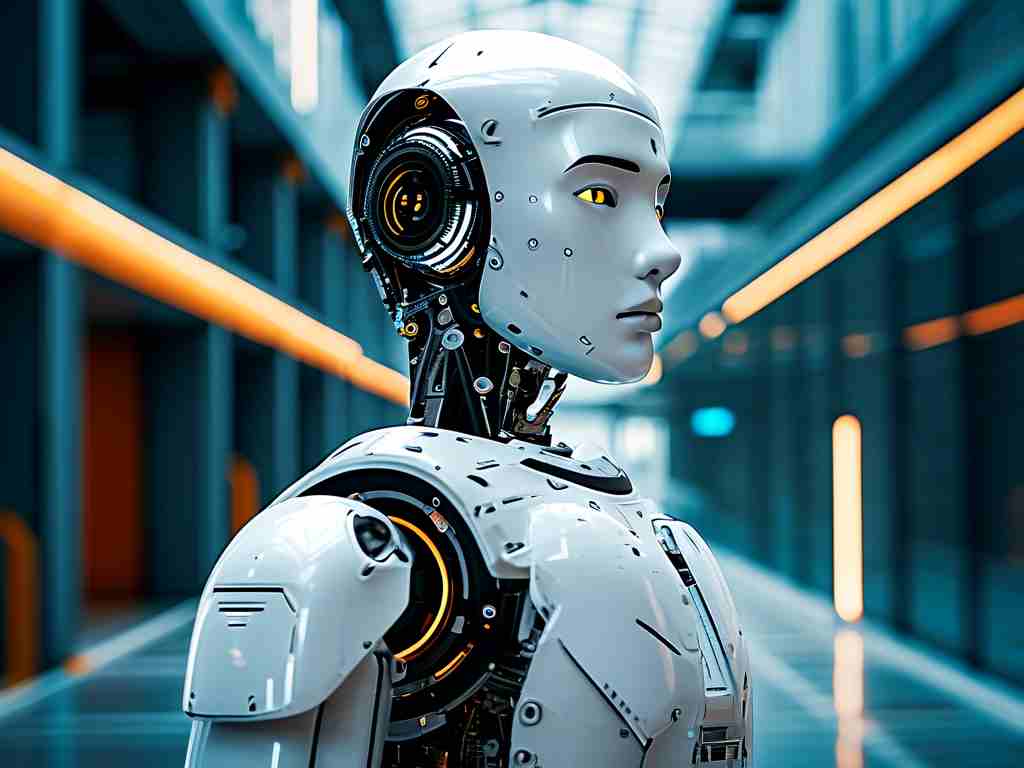

AI-Driven Automation:

Xuzhou ABB robots incorporate AI algorithms to optimize processes in real time. For instance, predictive maintenance systems analyze sensor data to anticipate equipment failures, minimizing unplanned outages. Machine vision systems enable robots to identify defects with sub-millimeter accuracy, ensuring consistent product quality. -

IoT Integration:

ABB’s Ability™ platform connects robots across factories, enabling centralized monitoring and data analytics. This IoT framework allows manufacturers to track performance metrics, energy consumption, and workflow bottlenecks, fostering data-driven decision-making.

Applications Across Industries

-

Automotive Manufacturing:

Xuzhou ABB robots dominate automotive production lines, performing tasks from welding and painting to component assembly. Their precision ensures compliance with stringent safety and quality standards, while their speed boosts output. For example, a major electric vehicle (EV) manufacturer in China reported a 40% increase in production efficiency after deploying ABB’s robotic arms. -

Electronics and Semiconductors:

In electronics, ABB’s SCARA robots excel at high-speed PCB assembly and microchip handling. Their ability to operate in cleanroom environments makes them indispensable for semiconductor fabrication, where contamination risks must be eliminated. -

Logistics and Warehousing:

Autonomous mobile robots (AMRs) developed in Xuzhou are revolutionizing logistics. Equipped with LiDAR and AI navigation, these robots streamline inventory management and order fulfillment in e-commerce warehouses, reducing human error and labor costs.

Economic and Social Impact

The adoption of ABB robotics in Xuzhou has spurred economic growth by attracting foreign investment and creating high-tech jobs. Local universities and vocational schools now partner with ABB to offer specialized training programs, bridging the skills gap and empowering workers to thrive in automated environments.

Moreover, ABB’s sustainability initiatives align with China’s carbon neutrality goals. Energy-efficient robots and smart energy management systems have helped manufacturers reduce their carbon footprint. For instance, a Xuzhou-based steel plant cut energy consumption by 25% after integrating ABB’s robotic systems.

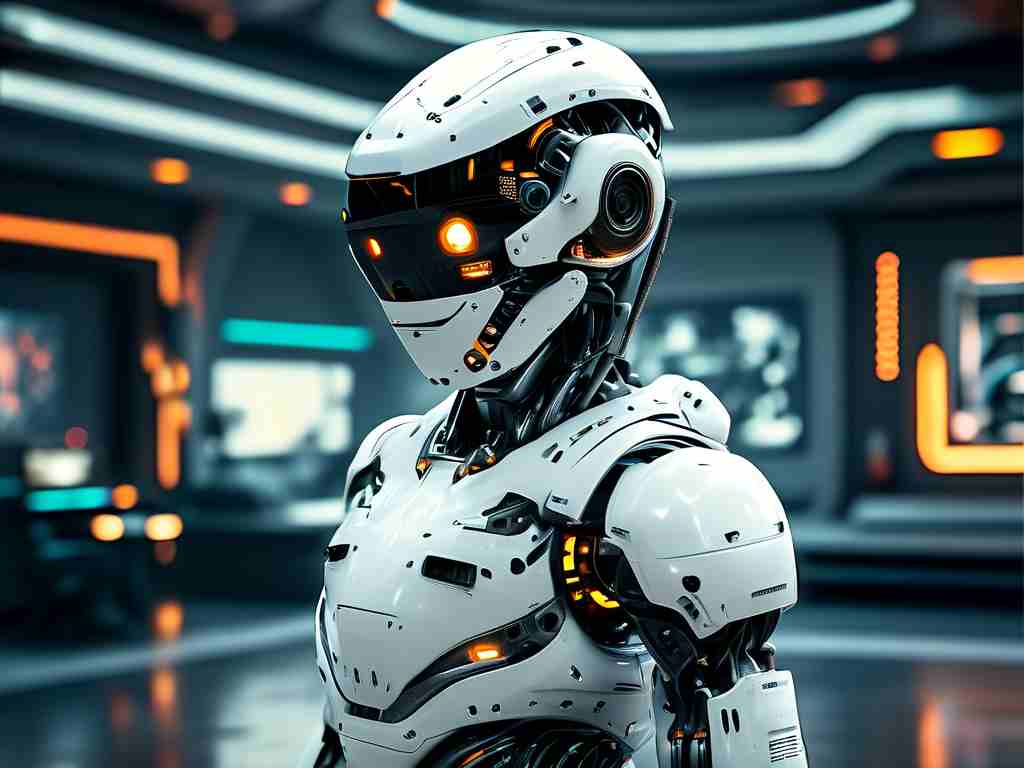

Challenges and Future Prospects

Despite its successes, the expansion of industrial robotics faces challenges. Cybersecurity risks, high initial investment costs, and workforce resistance to automation remain concerns. ABB addresses these by offering scalable solutions, robust encryption protocols, and educational outreach to demystify robotics.

Looking ahead, Xuzhou is poised to lead in next-gen robotics. ABB’s ongoing R&D in quantum computing, swarm robotics, and 5G-enabled automation promises to unlock new possibilities. Collaborations with startups and research institutes will further accelerate innovation, solidifying Xuzhou’s role as a global robotics powerhouse.

Xuzhou ABB industrial robotics represents the convergence of technology, strategy, and sustainability. By pushing the boundaries of automation, ABB is not only enhancing industrial productivity but also shaping a future where humans and robots coexist harmoniously. As industries worldwide grapple with digital transformation, the innovations emerging from Xuzhou offer a blueprint for success in the Fourth Industrial Revolution.